Production process

Precision machinery processing for round, square, elliptical and hexagonal parts.

Design, deployment and satisfaction

Our supply chain operates through well-defined production processes, which are an integral part of our certified quality procedures manual. Each step is identified and thoroughly monitored to ensure excellence in every product. We work according to the drawings and specifications of our customers, ensuring that each item is completed with all the necessary treatments. This approach enables us to deliver finished products to the highest standards, accommodating needs, time frames and expectations in a timely and accurate manner.

Processing phases

01 Arrival at the warehouse

Thorough inspection of materials to ensure quality and compliance with company standards. This is the first step towards transforming materials into outstanding products.

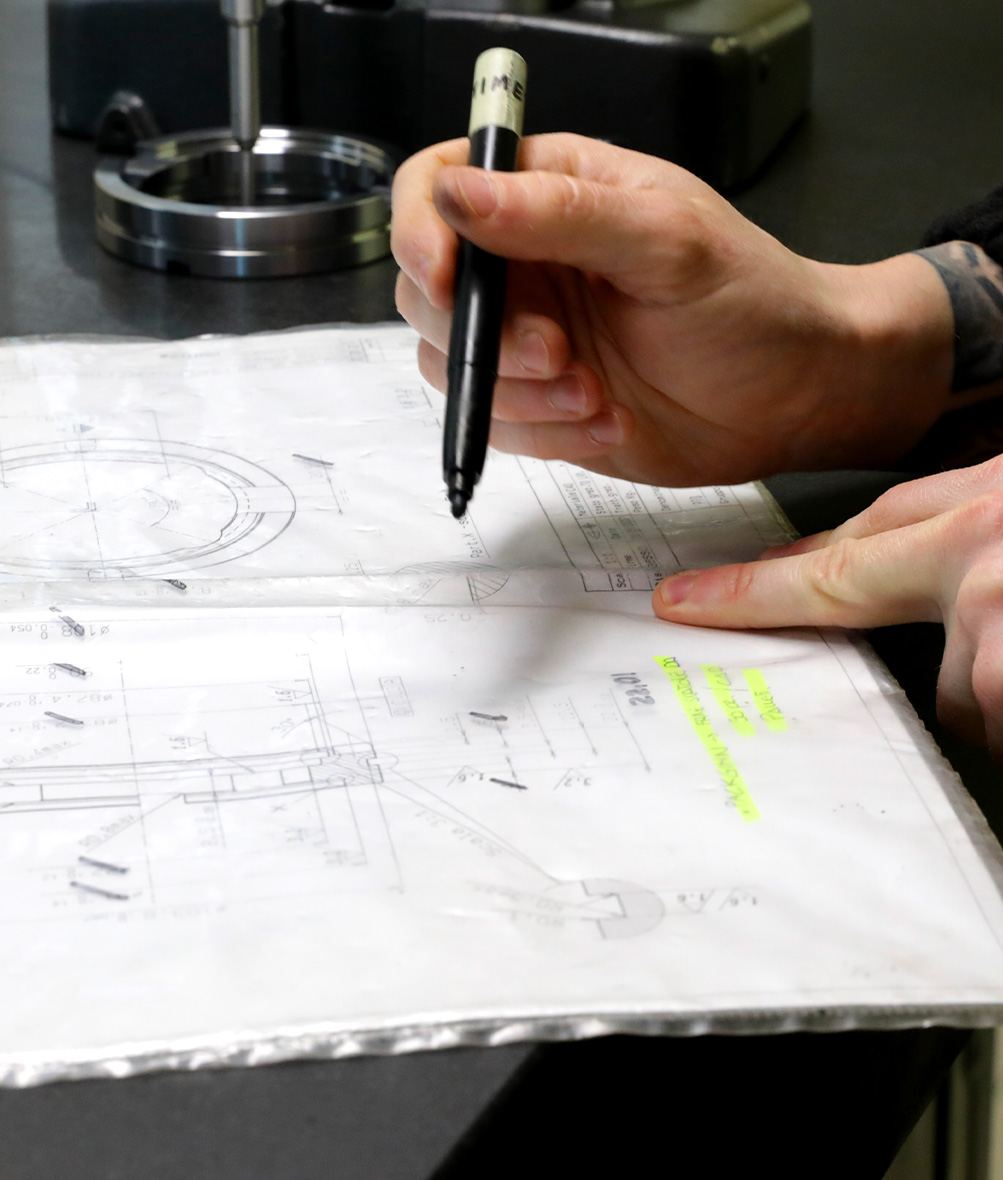

02 CAD CAM Programming

Every idea and project takes shape and is meticulously outlined in terms of dimensions, finishes, heat treatments and configurations.

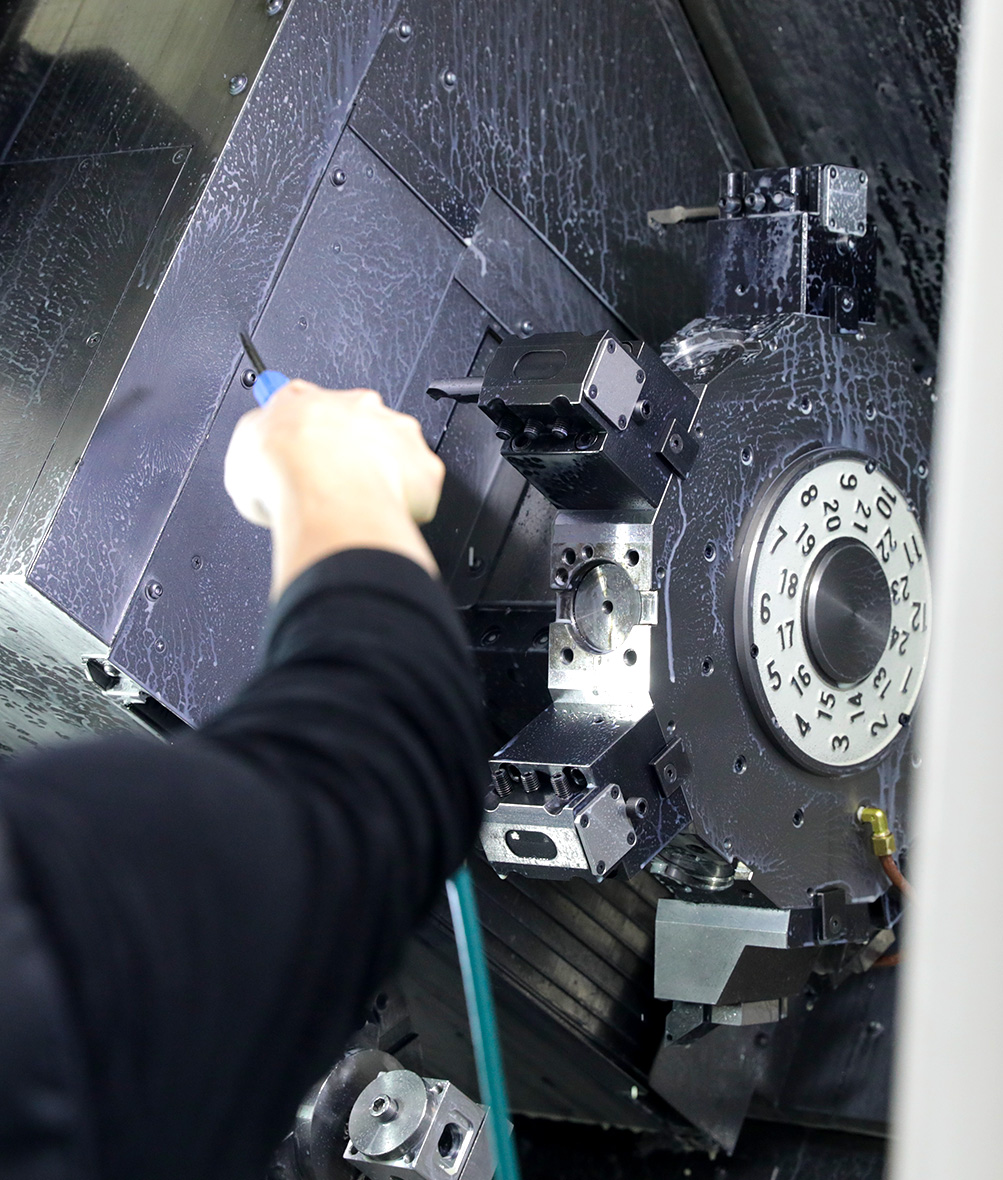

03 Mechanical milling and turning

CNC TURNING: From a Ø 4mm to a Ø 80mm bar, with remachining up to max Ø 300mm MILLING: Up to a cylinder of Ø 800 H 1000

04 Welding

This is a delicate process that requires qualified expertise to ensure the welding is carried out correctly and proves safe and durable.

05 Assembly

A crucial step which requires absolute accuracy to ensure optimal operation of the final product.

06 Metrology room

Equipped with state-of-the-art tools and equipment, allows the testing and dimensional control of every mechanical component.

07 Grinding

An ideal type of machining to achieve an impeccable surface finish with the utmost level of precision. We rely on trusted partners for this process.

08 Galvanic and heat treatments

Finishing operations that allow the product to be covered with another metal, to make it more resistant to corrosion, or which improve the quality of metals by altering the internal structure. We rely on trusted partners for this process.

Materials processed

Our dedication to quality is also reflected in the way we work on a wide range of materials.

Whether it’s stainless steel, special alloys, brass, aluminium or plastic, each one is treated with the utmost expertise: every step of the production process is subject to strict controls to ensure that the required standards are met.

Stainless steel

Known for its corrosion and rust resistance, it is ideal for applications where durability and reliability are required.

Alloy steels

They boast superior mechanical and thermal properties than carbon steels.

Brass

A copper and zinc alloy with excellent machinability properties and corrosion resistance.

Aluminium

Lightweight, corrosion-resistant and highly ductile.

Plastics

Lightweight, hard-wearing and flexible to use.

Titanium

Lightweight, corrosion-resistant and biocompatible.